The Journey of a Saree: From Loom to Drape

The saree—a six-yard wonder—is more than just a piece of fabric. It’s a symbol of tradition, artistry, and cultural heritage. But how does this elegant attire come to life? The process of saree making is a fascinating journey of craftsmanship, patience, and passion. In this article, we’ll take you behind the scenes, step by step, into the creation of a saree—from sourcing the threads to the final drape.

1. Sourcing the Fabric

The journey begins with choosing the right material. Sarees can be made from a variety of fabrics such as silk, cotton, georgette, chiffon, or linen. At our workshop, we primarily use handloom silks and organic cotton sourced from trusted weavers in South India. The quality of the thread determines the softness, shine, and durability of the saree.

We focus on eco-friendly, ethically sourced yarns, ensuring sustainability and comfort. Every batch of fabric is inspected for consistency and texture before moving on to the next step.

2. Spinning and Dyeing

Once the yarn is sourced, it’s spun into threads. Traditionally, spinning was done manually using chark

has, but today, both hand and power looms are used depending on the type of saree.

Dyeing comes next. Natural or synthetic dyes are used to color the threads. Our artisans specialize in natural vegetable dyes to retain purity and eco-safety. The threads are boiled, soaked, and dyed in large vats, often requiring multiple dips to achieve deep, rich hues. Once dyed, they are hung in the sun to dry naturally.

3. Designing the Pattern

Designing a saree is a creative art in itself. Each saree tells a story—through motifs, borders, and pallus. Designs may be traditional (like paisleys, peacocks, or temple patterns) or modern (like florals or geometrics).

We use a blend of hand-drawn sketches and digital patterns to guide our weavers. Custom designs can also be crafted for bridal or festive sarees. This is the stage where the identity of the saree is born.

4. Weaving the Saree

Weaving is the soul of saree making. It takes 1 to 7 days to weave a single saree depending on its complexity. Our weavers, most of whom come from generations of traditional artisans, work on wooden looms using either the pit loom or frame loom method.

This stage requires immense skill and concentration. Warp (vertical) and weft (horizontal) threads are interlocked manually or semi-automatically to form the fabric. Patterns are inserted through jacquard cards or hand techniques for precision.

5. Embellishing and Embroidery

After weaving, sarees may be further beautified with zari (gold or silver thread work), hand embroidery, mirror work, or sequins depending on the design.

Our in-house artisans specialize in hand embroidery that adds elegance without overpowering the natural beauty of the weave. This also allows us to offer limited-edition pieces that are truly one-of-a-kind.

6. Finishing and Quality Check

The finished saree is then washed, steam-ironed, and finished. Any loose threads are clipped, and the saree is given a final polish. A thorough quality check is performed to ensure that each piece meets our standards of craftsmanship.

We pack each saree in breathable cloth bags, along with a care card and a personalized thank-you note. Our commitment to detail ensures that when you open your saree, it feels like receiving a piece of art.

What Makes Our Sarees Unique?

- Handwoven by skilled artisans

- Natural dyes and organic fabrics

- Limited-edition designs

- Customizable for bridal or festive needs

- Ethical and sustainable production process

Each saree carries the warmth of our weavers’ hands, the stories of tradition, and the beauty of timeless fashion.

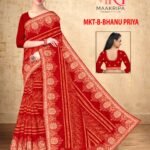

Bhanupriya

Bhanupriya